Automated Optical Inspection^wafer surface inspection system^YGK Corporation

TEL. +81-55-284-6866

595-2,Kuruwada Minami-Alps,Yamanashi 400-0311,Japan

xoh|lw|ฆ@cbFor SiN wafer, GaN wafer, or transparent wafer.

- New designed detection units which are cross

setting with dual 355nm (UV) laser.

The dual detector contributes enhanced detection for a slight scratch generated directional light scattered compared with conventional particle inspection system.

And also, 355nm laser is effective for isolated detection of SiC surface only.

Inspection time is within 5min for 4inch SiC wafer.

@@@@

@@@@

@@@@dual laser units@@@@@@@@@@@@@@@@@@@Inspection result image

@

- Transparent wafer, silicon wafer or LT wafer can be measured by YPI-MX-ฦDC. Maximum sensitivity is 0.1สm.

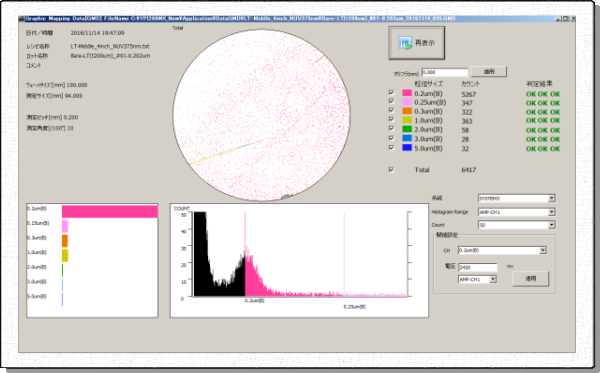

MAP result for LT wafer

Approx 2minutes inspection time for 4inch LT wafer.

Specifications

- Scanning method

- Rotation or XY scanning with dual laser units

- Work piece setting

- Manual or Auto loading (Cassette to Cassette)

- Electric consumption

- AC100V/200V 30A

- Maximum sensitivity

- 0.1สm

- Reproducibility

- ะ^w PO

- Inspection time

- Within 2 minutes for 4inch wafer

- Target substrate and wafer

- SiC waferAGaN waferALT waferAfilm deposited waferA

Transparent substrate and wafer - Appearance Dimension

- vXOO~cP,OOO~gP,VTViManualj

vP,TRO~cP,QOO~gP,VPTiAuto loadingj - Weight

- Approx.TOOiManualj

Approx.POOOiAuto loadingj

oi[Xy[X

YGK Corporation

595-2,Kuruwada Minami-Alps,

Yamanashi 400-0311,japan

TEL +81-55-284-6866

FAX +81-55-284-6867